Italian innovation, rich history and trail-blazing success, Scarpa are one of the oldest and most famous creators of mountain-based footwear in the world. What originally started as a mountain boot company in 1938 has since evolved and grown into one of the world’s leading producers of footwear for the outdoors. In recent years this success has come from their superb range of rock climbing shoes; in this article, we’re taking a deep dive into Scarpa’s shoe making process and the technology that defines their market leading status.

Image above: Nico Favresse using the Scarpa Booster to clinical effect.

The Mariacher Effect

After over 30 years of mountain boot production, Scarpa designed their first climbing specific shoe in the 1970’s. Typical of the time, Scarpa’s first forays into the climbing shoe business were largely influenced by the contemporary rock shoes of the day from the leading brands of the era like Boreal and EB. Scarpa’s first climbing shoe models like their popular Rockmaster featured a similar high-top design with a flat, stiff last.

Scarpa continued making climbing shoes, slowly building a reputation as a respected shoe manufacturer with popular models like the Cragratz and Superatz but, it wasn’t until the mid 2000’s when the Scarpa we know today really took shape. It was the 2006 introduction of distinguished shoe designer Heinz Mariacher that truly revolutionised Scarpa’s climbing shoe operation. His impact on the Scarpa team was instantaneous as he swiftly introduced the first female specific line-up of shoes as well as playing a key role in the creation of the Instinct range – the shoes that defined Scarpa’s evolution into the climbing shoe force that dominate the market today. After over 15 years in the job and having created an impressively eclectic range of market leading performance shoes, the Mariacher effect is clear for all to see. But, who is Heinz Mariacher?

Heinz Mariacher, although likely a lesser known figure amongst the wider climbing community today, was already a revered figure in the climbing shoe industry by the time he joined Scarpa in ’06. A climbing legend in the 70’s and 80’s, Heinz was known for his daring trad leads and solo alpine ascents in the Alps and Dolomites, pushing the European free climbing standard to new levels. Throughout the 80’s Heinz switched his focus to the growing sport climbing scene where he proved to be just as successful but, it was the job he started with La Sportiva at the start of that decade that really defined his career. Mariacher joined the Sportiva team as a climbing shoe consultant, using his years of climbing experience to help them develop new rock shoes and, over the coming decades went on to craft a host of iconic models. So, it’s no surprise that upon his arrival in 2006, Mariacher’s effect on Scarpa was profound, but why? Let’s find out.

Image above: Heinz Mariachar with one of his creations in hand (image credit - Gianni Antoniali).

Shoe making process

Heinz and his team are responsible for a large part of any Scarpa shoe’s research and development before it enters production. From sourcing specific materials to deciding which make the cut and are used on the final product, Heinz and his team are meticulous in finding the perfect materials and construction methods to execute their vision and design brief for every shoe in the range.

Lasts

Where Heinz has made his name over the years has been his ability to craft ingenious new shoe lasts, designing countless classics and the world’s first downturned shoe as early as the 1990’s. Arguably one of Heinz’s greatest successes at Scarpa has been his design of female specific lasts, creating a last to specifically suit the lower volumed shape of women’s feet. His first women’s design at Scarpa, the Rockette, was a roaring success and gave rise to the lower volumed, women’s alternatives to most of the Scarpa models on sale today. Whilst built for women, it's worth noting that Scarpa's range of women's shoes and their Low Volume models (the Instinct WMNS and the Drago LV for example) are both incredibly similar in construction and actually feature many of the same differences to their regular parent model. So, whilst women's models are engineered for women's feet, they can also be thought of as a low volume alternative for men with narrower feet - Scarpa athlete Aidan Roberts is a big fan of the women's Instinct Lace.

Check out our Scarpa Women’s collection here.

Image above: Nina Caprez taking it easy in her pair of Instinct VS Women's.

Image above: Nina Caprez taking it easy in her pair of Instinct VS Women's.

What is a last? A last is essentially a 3D positive mould that forms the template of a climbing shoe's profile, giving it the characteristics that will define its finished design and the way it performs on the rock; to create this unique shape Heinz will work painstakingly to carve an initial model that embodies his new shoe’s concept. Although this might seem like a simple task, the creation of these lasts is incredibly complex and Mariacher’s expertise here has been the crucial factor behind the Scarpa range’s unrivalled fit and performance.

Once this last has been perfected and prototypes have been made, the last and its different shoe size variations will go into full scale production with an individual last being produced for every Scarpa climbing shoe made. If, for example, a Scarpa production run manufactured 30 pairs of size 42 Instinct VSR (as well as however many they’ll need in every other size), they’ll need 30 pairs of lasts just for that size! Along with the other skilled, handmade aspects of European climbing shoe production, this logistical and time limiting factor is well worth considering when you consider the price of your next climbing shoe.

In the case of specific Scarpa shoe ranges, a last’s design will be used for multiple shoes to give the range continuity in fit and feel - within the Instinct range for example, the Instinct VS, VSR and Lace all share the same FV last, the differences in fit and performance attributes come through the varying materials, tensioning and construction methods used to create the upper. The last forms a shoe’s building block, providing the base for a shoe’s construction - the next step in the production process is the addition of soft materials and the upper.

Image above: The evolution of lasts from the flatter, traditional fit of the Scarpa Vantage (over 10 years old) to the modern, downturned profile of the Scarpa Drago.

Image above: The evolution of lasts from the flatter, traditional fit of the Scarpa Vantage (over 10 years old) to the modern, downturned profile of the Scarpa Drago.

Soft materials

Scarpa’s climbing shoes are initially formed by a ‘slip lasting’ process that involves the shoe’s soft materials being sewn into a sock shape before being fitted to the last. Once on the last, this sock-like shape forms the building block for Heinz's vision with the subsequent parts and technologies being carefully glued to the sock. When we think of gluing, we might be forgiven for thinking of a primary school PVA sticking scene but, in the case of performance climbing shoes, this job is highly skilled and requires special care to ensure the tensioning of the shoe is just right. The soft materials Scarpa source for their shoes form the foundation of their shoe’s success with Heinz and his team again taking the time to find the best fabrics for the job.

To further contextualise this, Scarpa’s initial soft ‘sock’ is created from up to 8 panels of individual, dual-ply fabrics. Technical Scarpa models utilise these dual-ply fabrics alongside drilled holes in the fabrics and rubber to balance stretch in zonalized areas whilst maintaining the fit and shape over the shoe's lifespan. These unique fabrics each play a role in making Scarpa’s climbing shoe experience the comfiest and most streamlined around, certainly distinguishing them as a cut above the competition who usually create their socks from 2-3 panels of fabric. But, what are these panels for? Each panel is selected for a specific task, whether this is the Alcantara patch wrapping around the big toe of the Chimera to boost its sensitivity and comfort or the microfibre toe pocket design of the Mago which ensures the toes are buckled in for unbeatable edging power. Using a mixture of both leather and synthetic microfibres across the different panels of the shoe, Scarpa expertly engineer their shoes to interact with the foot in different ways, stretching and relaxing in some areas whilst synching the foot in securely in others.

Do Scarpa produce Vegan friendly shoes? Whilst most of Scarpa's shoes are made from vegan components, a lot of their high-performance options use a leather footbed, as it retains higher performance levels when the feet become hot and sweaty - offering massively improved grip between the toes and the shoe over synthetic materials. But, yes, aside from the models that feature this leather footbed, Scarpa do produce plenty of shoes which feature no animal products, check them out below:

Vegan Friendly Shoes

Quantic

Quantic WMN

Veloce Lace (coming in 2023)

Veloce Lace WMN (coming in 2023)

A notable mention with regards to Scarpa’s soft materials has to be their ultra-comfortable Reflex range which has been designed to suit indoor climbers that are experiencing the sport for the first time. The Zonal stretch knit fabric upper on the Reflex is fantastically breathable, supportive and washable, whilst boasting Vegan friendly credentials to boot.

Image above: A collection of Scarpa's soft materials alongside the last and sock design of the Drago.

Image above: A collection of Scarpa's soft materials alongside the last and sock design of the Drago.

Midsoles

The next layer to be added to the shoe is the midsole, a thin (often 1mm) piece of ‘Flexan’ plastic which reinforces certain areas of the shoe. Scarpa, unlike much of their competition, use midsole technology on all of their shoes. Even Scarpa’s softest models include a midsole, like the Furia for example, which has a small midsole insert under the big toe of the shoe to provide support on small footholds and enable the shoe to hook efficiently in conjunction with its sensitive profile. On edging focussed models like the Boostic however, the midsole is more profound, spanning the length of the shoe and even encroaching up the side of the toe box to deliver ultimate edging power and keep the foot planted securely on any foothold.

TPS (Toe Power Support) System

An exception to the widely used Flexan midsole is Scarpa’s TPS system, a stiffer, thermoshapable insert positioned under the forefoot of models like the Chimera which supports the toes more when edging but doesn’t restrain the foot when smearing.

Image above: This should give you a better idea of how Scarpa’s Flexan midsoles look; you might notice the Furia’s midsole, like the Booster’s, has a hole in the middle - this is to slightly decrease its rigidity, enabling it to flex more when the shoe smears and hooks.

Tension systems

Once the midsoles have been fitted to the sock, it's time to add some rubber and although midsoles are the obvious platform stiffener, Scarpa’s tension systems arguably play a bigger role in determining the flexibility and feel of their shoes. A tension system is a technology that comes in many different guises across the Scarpa collection, ranging from the simple and widely used Bi-tension rand wrapping around models like the Vapour to the CTS system deployed on the Instinct S which fully envelops the shoe. Tension systems, made from stiffer rand rubber, are designed to maintain the shoe’s shape whilst controlling its flexibility or rigidity. Some of Scarpa's most notable and widely used tension systems are detailed below:

PCB Tension

The Power Connection Band transfers power from the toe to the heel, allowing the shoes to fit like a sock with power and sensitivity.

Bi-Tension

Instinct Range | Instinct WMN’s Range | Vapour Range

Basically, a reverse slingshot rand that's anchored under the critical toe area and connects directly to the heel rand, only there's nothing basic about it. Bi-Tension actively pulls power from the toes, rather than cramming your toes painfully forward, giving immediate performance with less tension. This means less rubber, making your shoes lighter, more sensitive and more reactive.

DTS Tension

Booster | Boostic | Veloce Range

The DTS tension system adapts perfectly to the dynamics of the foot in motion.

The Differentiated Tension System concentrates power onto the big toe without interfering with the fit in other parts of the shoe. This helps keep the foot and toe in optimal position for power transfer and precision.

PAF System

Drago LV | Furia Air | Boostic | Booster | Instinct WMN | Vapour Range | Veloce Range | Reflex Range

PAF is an innovative heel system that helps both spread the force of the heel tension, which also helps with over-compression of the toe box, and improves the fit of the heel. Providing uninterrupted contact with the rock (thanks to less seams and rubber joints around the heel) the PAF system is a top choice for Scarpa's leading outdoor athletes with the likes of Aidan Roberts (see his use of the Instinct Lace WMN's on his recent ascent of Isles of Wonder SS 8C+) and Dan Varian opting for Scarpa models that feature the PAF heel. The aggressive tension-rubber is interrupted behind the heel to reduce pressure on the Achilles tendon and connected with softer rubber, that works like a bridge and allows full adaptation to the shape of the heel. The holes on the side of the heel indicate the tension applied, which varies between 1 hole for light tension, 2 holes for mid tension and 3 holes for strong tension.

PAF is an innovative heel system that helps both spread the force of the heel tension, which also helps with over-compression of the toe box, and improves the fit of the heel. Providing uninterrupted contact with the rock (thanks to less seams and rubber joints around the heel) the PAF system is a top choice for Scarpa's leading outdoor athletes with the likes of Aidan Roberts (see his use of the Instinct Lace WMN's on his recent ascent of Isles of Wonder SS 8C+) and Dan Varian opting for Scarpa models that feature the PAF heel. The aggressive tension-rubber is interrupted behind the heel to reduce pressure on the Achilles tendon and connected with softer rubber, that works like a bridge and allows full adaptation to the shape of the heel. The holes on the side of the heel indicate the tension applied, which varies between 1 hole for light tension, 2 holes for mid tension and 3 holes for strong tension. SRT

A layer of ultra-soft M50 rubber that wraps around the forefoot and translates power directly to the tips of the toes. It provides maximum friction and sensitivity for toe-hooking whilst making the shoes softer which improves one’s climbing style and naturally strengthens toe power.

Image above: An example of a Scarpa tension system, this particular one being the DTS system from the Boostic.

Rubber

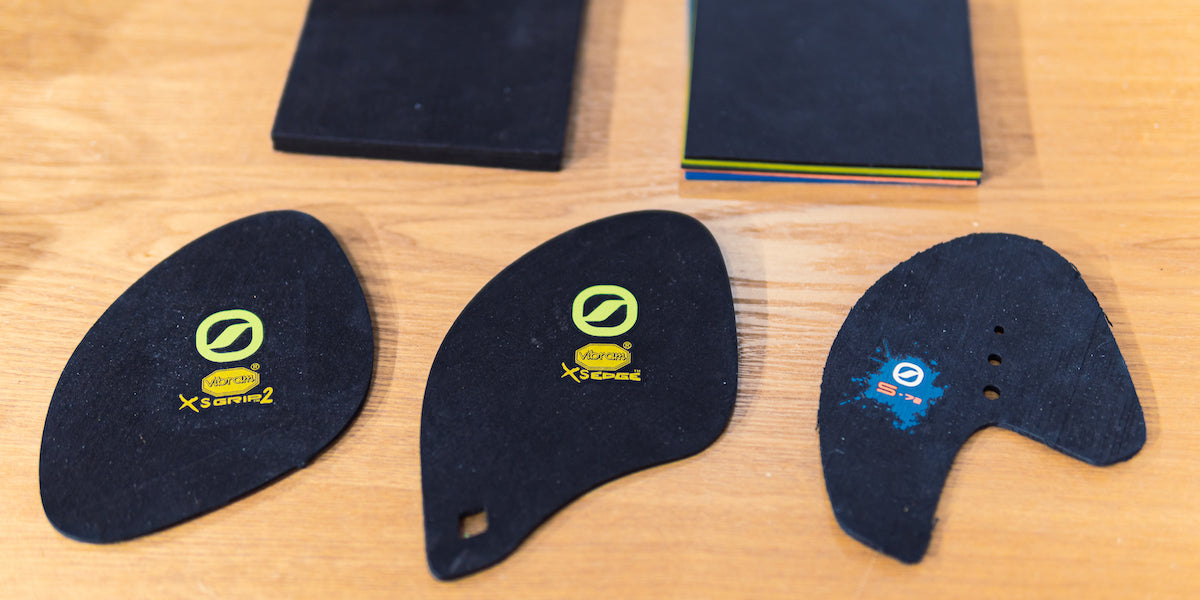

The last technical element to be perfected on a Scarpa shoe is the rubber and whilst this might seem like one of the simpler tasks along the production line given the majority of Scarpa’s rubber comes from Vibram, Scarpa have invested a lot of time in sourcing other rubbers that complement Vibram’s supreme lineup. With such an eclectic range of shoes, it's imperative that Scarpa choose the right rubber for the job and it's in sourcing their own rubbers on top of Vibram's lineup that Scarpa ensure each shoe has the perfect rubber for its intended terrain. Here's the low down on each of Scarpa's rubber compounds:

Vibram XS Grip 2

Chimera | Drago | Instinct VS WMN

Vibram XS Grip 2 delivers the highest levels of grip with a level of firmness ideal for moderate edging while maintaining consistent performance in all temperatures. Vibram XS Grip 2 is used on the soles and toe patches of Scarpa's softer high performance shoes where maximum grip is key - ideal for indoors, outdoor projects and sedimentary rock types like gritstone.

Vibram XS Edge

Boostic | Instinct Lace | Vapour V

Developed to provide unrivalled edging support, the Vibram XS Edge compound delivers excellent grip and unbeatable performance when standing on small footholds. Thanks to an improved resistance to plastic distortion, it keeps its shape even after hours of use and maintains consistent feel in both hot and cold temperatures. The stiffest and most durable performance rubber from Vibram is used by Scarpa on the soles and toe patches of their technical, edging focussed models - ideal for outdoor climbing and all day support, especially for heavier climbers who will feel the benefits of added support.

Davos S72

S72 is a super high friction sole rubber, developed and tested by Scarpa. This soft compound gives a Shore A rating of 72, making it very adaptable to any surface and provides incredible grip on mixed climbing terrain. Used by Scarpa on the Veloce's, the S72 is Scarpa's go-to indoor rubber - ideal for smearing whilst climbing both indoors and outside on sedimentary rock types like fine grained grit or sandstone. S72 isn't recommended, however, for use on sharp rock types with its softer properties better suited to and more durable when smearing and indoor climbing.

Davos M50

SRT System

M50 is Scarpa's softest rubber compound offering the best levels of adaptability to the natural profile of the foot and toes. This morphing rubber compound gives a Shore A rating of 50, making it perfect for use in the SRT system (see tension systems above for more information), toe patches and strategic positioning around the shoe upper. Its lower density, high friction properties and extreme elasticity make it perfect for use on the uppers of shoes where the forces applied are lower - toe hooks, foot cams etc. For the same reasons, its cohesion is too low to be used on the sole area of a shoe, where the full load of a climber’s body weight will go beyond its tear resilience.

Vision

Piki J | Reflex V | Velocity V

Scarpa’s Vision rubber is a proprietary compound that's both sticky and resilient to all the conditions that new climbers will experience. Built with durability in mind, Scarpa's Vision sole rubber is ideal for newer climbers looking to perfect their technique in their first pair of shoes.

Ilga

Rand RubberIlga rubber is Scarpa's primary compound for rand systems. Stiffer than their other compounds, the Ilga rubber helps keep Scarpa's shoes rigid in all the right places. An example of its use is on the Instinct S where Ilga rubber is used on the instep of the toe box to keep this area stiffer and more uniform for better performance on small edges.

Image above: Some examples of the rubber templates that make up the toe patch of some Scarpa shoes. 1. The M50 rubber used on an SRT toe patch. 2. The SX Edge toe patch from a Scarpa Instinct VS. 3. Scarpa's own M70 rubber toe patch used on the Vapour shoe series.

Image above: Some examples of the rubber templates that make up the toe patch of some Scarpa shoes. 1. The M50 rubber used on an SRT toe patch. 2. The SX Edge toe patch from a Scarpa Instinct VS. 3. Scarpa's own M70 rubber toe patch used on the Vapour shoe series.

Image above: 3 of Scarpa's rubber compounds -

Image above: 3 of Scarpa's rubber compounds -

(rubber from left to right) Vibram's XS Grip 2, Edge and Scarpa's own S72 found on the Veloce.

Resoling

As more climbers become environmentally conscious and with the price of climbing shoes on the rise, resoling is becoming a growing part of the market. Something that really stands out about Scarpa shoes and their latest rubber units from Vibram is just how easy and efficient they are to replace and resole. Scarpa have two approved resolers for their climbing shoes and each resoler can replace your Scarpa shoe’s rubber with whichever Vibram compound you fancy - pretty cool. Check out Scarpa's approved resolers below.

Llanberis Resoles - At the heart of the Welsh climbing scene, Llanberis Resoles offer a quick turnaround and a streamlined resoling process.

Chida - London based.

Images above: The finished Scarpa Drago build, from last through to the finished product with every bit of technology in between.

Images above: The finished Scarpa Drago build, from last through to the finished product with every bit of technology in between.